Menu

In recent years, Magotteaux decided to implement an SAP system to streamline order and production management. At the Magog plant, the in-house X-Métal and X-Charge software, long used to manage production, had become unstable, difficult to maintain, and incompatible with the new SAP system. Since Magotteaux wanted to replace its systems gradually, Kezber needed to make the IT infrastructure compatible with SAP while still using the existing Oracle 9 database, despite the obsolescence of its connectors. Additionally, Kezber had to automate certain tasks to reduce errors and increase the plant’s productivity.

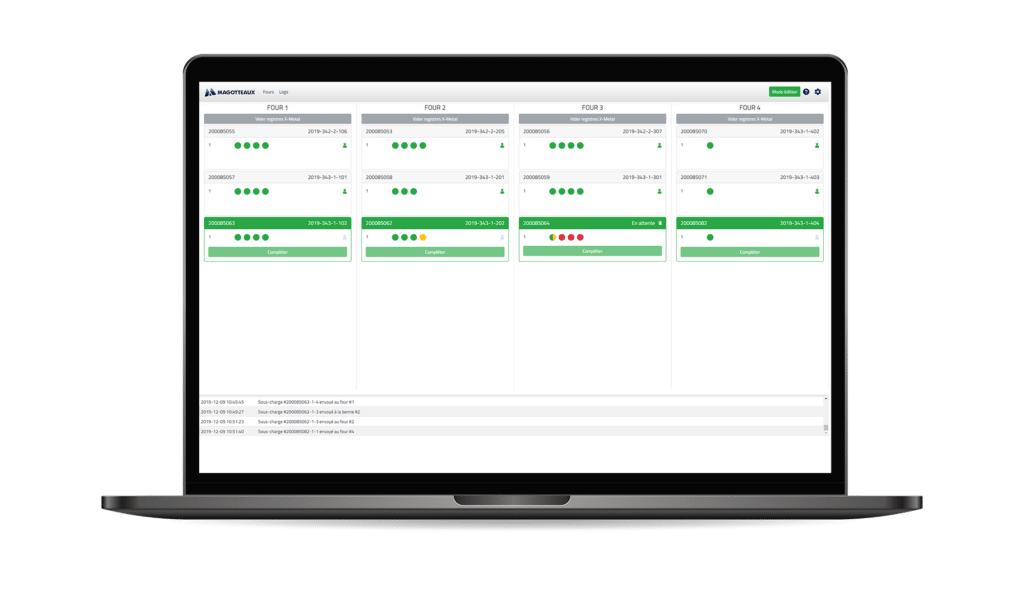

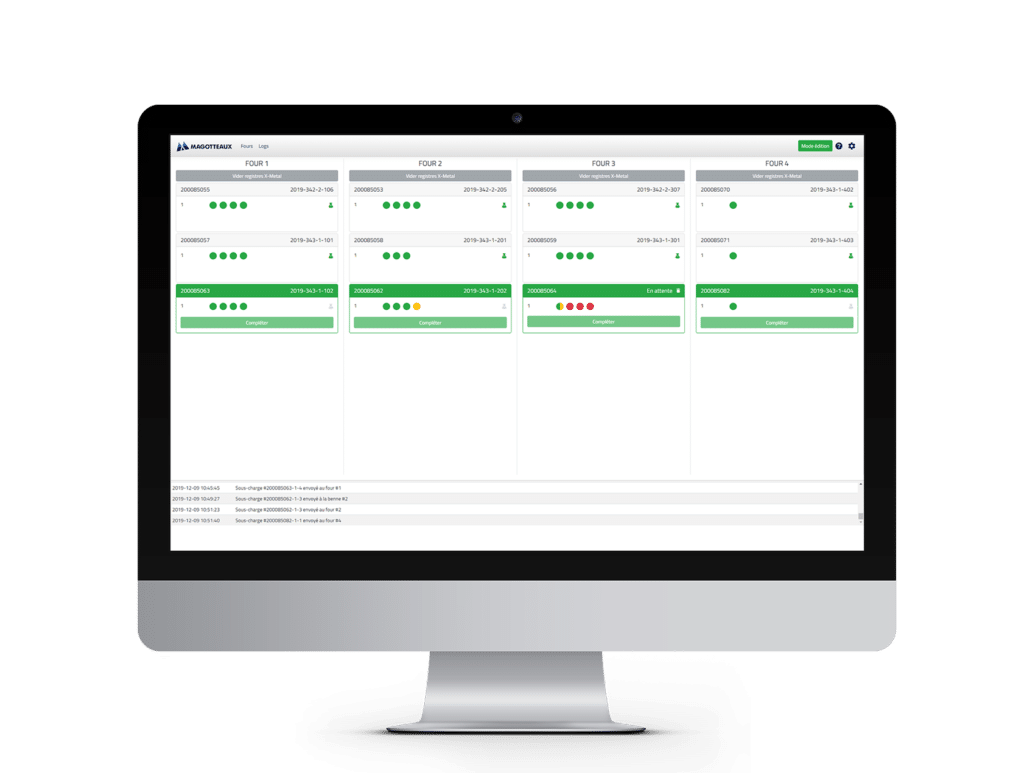

Kezber’s solution was to replace X-Métal with a new custom application, X-Splitter, to meet the compatibility needs of the Magotteaux plant in Magog. After virtualizing the production servers to recreate the development environment, Kezber collaborated with Magotteaux’s team to develop X-Splitter, which communicates with both SAP and the existing Oracle database. Some functions previously managed by X-Métal are now handled directly by SAP via X-Splitter. Kezber also adapted X-Charge to link X-Splitter to the plant’s automated systems and modified the Oracle database to make it compatible with SAP.

«We want to highlight the efficiency and quality of Kezber’s expertise in delivering a key project for Magotteaux, impacting the core of our Canadian operations while meeting tight deadlines. This partnership aimed to achieve the agreed-upon objectives despite constraints and the constant need for flexibility.

The collaboration with Kezber was a true partnership—an increasingly rare and valuable relationship in today’s professional world. Thank you, Kezber !»

Thanks to the collaboration between Kezber and Magotteaux, the Magog plant now operates on the same IT infrastructure as the group’s other facilities. The integration of X-Splitter, which directly communicates with both SAP and X-Charge, has automated the grinding ball production process, reducing human intervention, minimizing error risks, and increasing productivity. Once the system upgrade is completed, the environment will be more stable and easier to maintain, allowing administrators to adjust production settings directly through X-Splitter.

Founded in Belgium in 1918, Magotteaux is the world leader in optimizing crushing and grinding processes, providing its products and services to the mining, cement, coal-fired power, and quarry industries. Working closely with its clients, Magotteaux designs, manufactures, and monitors the performance of grinding media and wear parts. With the most extensive range of crushing and grinding products, Magotteaux operates 38 offices, 12 production units, and employs 2,500 people worldwide. The Magog plant, integrated into the group since 1979, employs approximately 140 people and produces 54,000 tons of grinding balls annually for the mining industry.

Kezber © 2025 - All rights reserved by Signé François Roy.